Five key benefits of Inventory-as-a-service

Agilitas CEO Shaun Lynn explains the potential of the emerging channel service

The growth of the cloud and the evolution of the mobile workplace have altered demand for IT spares. With less organisations managing their own on-premise data centre, where and when spares are needed has changed. At the same time, a higher reliance on IT has meant any period of downtime will cost significantly, with just one hour estimated to cost 54 percent of end users between £10,000 and £1m. This new status quo puts more pressure on resellers, service providers and OEMs to better provision for faults and provide customers with an effective service. Inventory-as-a-service from a trusted partner can go a long way to help achieve this. These are the key benefits:

1. Costs are OPEX not CAPEX

Maintaining an IT hardware spares inventory has always been a high cost area for businesses. According to research, nearly 30 percent of resellers and service providers are spending over £50,000 a year on spare inventory for customers, with the figure rising to more than £1m in 20 percent of cases.

The cost of inventory-as-a-service is usually benchmarked as an operational expense that doesn’t change – an approach in line with demand according to Cisco chief Chuck Robbins, who recently commented customers are “fundamentally more concerned about the operational costs of their IT infrastructure than the CAPEX.”

2. IT parts expenses can be reduced

Keeping costs down and driving efficiency are two of the most vital qualities of any business. Provisioning for any spare part that might be needed is always going to be expensive, especially as there is rarely any indication as to what will be required when. Parts are often going totally unused. Our research revealed a quarter of providers are spending hundreds of thousands of pounds just to keep up with customer requirements for spare inventories. At what point does this go from being a simple budgeted overhead to an unavoidable cost that threatens a company’s growth plans?

A good inventory-as-a-service partner will have their own multi-vendor/technology repair centre and test rigs. These ensure parts are reused, reducing waste, unnecessary expense, and driving down operational costs further.

ChannelPro Newsletter

Stay up to date with the latest Channel industry news and analysis with our twice-weekly newsletter

3. Two hour SLA

Business is being conducted more quickly, and as a result customers are demanding instant inventory services. Whereas previously, four hour service level agreements (SLAs) were the norm, this has quickly been halved to two. High speed delivery is essential to maximising uptime. However, the potential fallout from any failure to meet SLAs can be significant, which is where inventory-as-a-service is pivotal.

For OEMs, service providers and resellers alike, ensuring the right support is in place can determine the success of a product or IT service. The logistics and management behind IT services are all invisible to the customer most of the time, but when required, performance needs to be meeting SLAs 99 percent of the time regardless of technology or vendor.

4. Training

One of the lesser recognised benefits of inventory-as-a-service is training. Good partners enhance the ability to meet two hour SLAs by upskilling existing field engineers and on-site technical staff to resolve some faults themselves. The inventory partner will ensure an IT spare part is rapidly delivered to the customer site and a member of their technical staff will swap it for the faulty one, with the knowledge that additional technical resource is on-hand should it be required. This means that costs can be reduced as less callouts are required, whilst helping to keep downtime to a minimum and increasing operational efficiency.

5. Remote support

In addition to upskilling existing staff, inventory-as-a-service partners are able to deliver rapid fault resolution by carrying out fixes remotely. Skilled engineers can take a member of on-site staff through a simple process to ensure network fault resolutions can be made without a call-out. Equally, as we become more dependent on technology, downtime can be reduced as an experienced remote engineer can be working on getting something fixed within seconds of it going wrong.

Managing inventory is always going to be a challenge for a non-specialist business, as getting the correct ratio of spares to existing technology is expensive, and engineers in the right place and time don’t come cheap either. The growth of mobile and cloud technology has altered demand, however the key aim remains to be maximum uptime. Inventory-as-a-service ensures networks are repaired quicker than any alternative. The need to explore a high performance, efficient and cost-effective inventory–as-a-service-solution is now greater than ever, not only for end user companies but their IT service providers.

Shaun Lynn is CEO of Agilitas

-

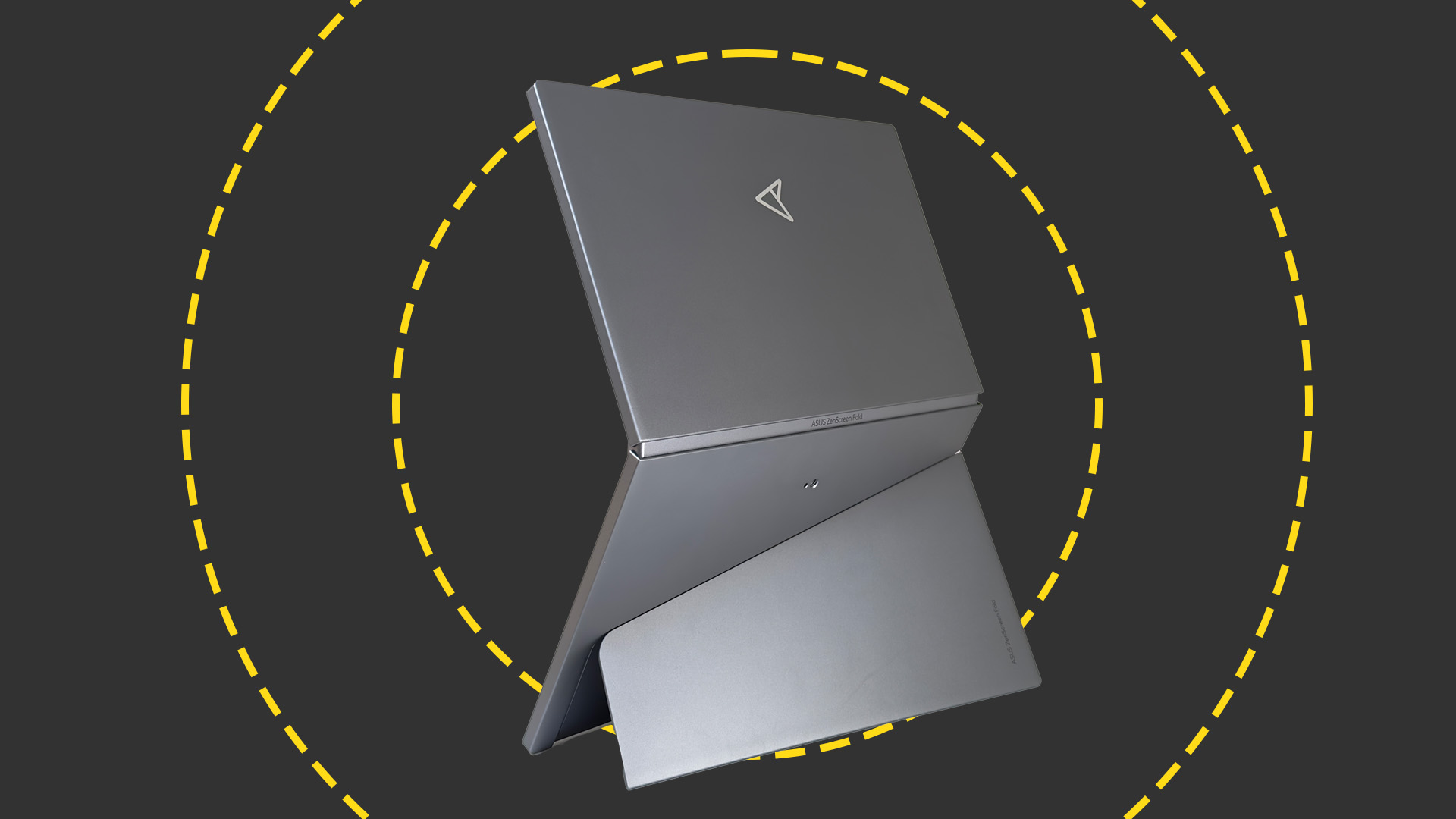

Asus ZenScreen Fold OLED MQ17QH review

Asus ZenScreen Fold OLED MQ17QH reviewReviews A stunning foldable 17.3in OLED display – but it's too expensive to be anything more than a thrilling tech demo

By Sasha Muller

-

How the UK MoJ achieved secure networks for prisons and offices with Palo Alto Networks

How the UK MoJ achieved secure networks for prisons and offices with Palo Alto NetworksCase study Adopting zero trust is a necessity when your own users are trying to launch cyber attacks

By Rory Bathgate

-

How to empower employees to accelerate emissions reduction

How to empower employees to accelerate emissions reductionin depth With ICT accounting for as much as 3% of global carbon emissions, the same as aviation, the industry needs to increase emissions reduction

By Fleur Doidge

-

Worldwide IT spending to grow 4.3% in 2023, with no significant AI impact

Worldwide IT spending to grow 4.3% in 2023, with no significant AI impactNews Spending patterns have changed as companies take an inward focus

By Rory Bathgate

-

Report: Female tech workers disproportionately affected by industry layoffs

Report: Female tech workers disproportionately affected by industry layoffsNews Layoffs continue to strike companies throughout the tech industry, with data showing females in both the UK and US are bearing the brunt of them more so than males

By Ross Kelly

-

How can small businesses cope with inflation?

How can small businesses cope with inflation?Tutorial With high inflation increasing the cost of doing business, how can small businesses weather the storm?

By Sandra Vogel

-

How to deal with inflation while undergoing digital transformation

How to deal with inflation while undergoing digital transformationIn-depth How can organizations stave off inflation while attempting to grow by digitally transforming their businesses?

By Sandra Vogel

-

How businesses can use technology to fight inflation

How businesses can use technology to fight inflationTUTORIAL While technology can’t provide all the answers to fight rising inflation, it can help ease the pain on businesses in the long term

By Sandra Vogel

-

Embattled WANdisco to cut 30% of workforce amid fraud scandal

Embattled WANdisco to cut 30% of workforce amid fraud scandalNews The layoffs follow the shock resignation of the company’s CEO and CFO in early April

By Ross Kelly

-

Some Tech Nation programs could continue after Founders Forum acquisition

Some Tech Nation programs could continue after Founders Forum acquisitionNews The acquisition brings to a close a months-long saga over what the future holds for Tech Nation initiatives

By Ross Kelly