‘Not if, but when’: Where are the autonomous robots?

Robots are already common in manufacturing, but where are the autonomous robots of the future and what form will they take?

Since the arrival of the first industrial robots back in the 1970s, robots have been grabbing a bigger and bigger role in the world economy, in a way that few people have been able to see.

“Everything you eat, or medication you take, or vehicle that you get into has been touched by robots,” says Simon Watson, a reader in robotics systems at the University of Manchester. Industrial robots are ubiquitous but invisible, he says: they toil in factories that you will never see inside, but they have a huge impact on your everyday life.

“Our entire world has already been shaped by robots. They do so much that we don’t ever see,” he adds.

But soon the robots will be hidden no more. A new generation of autonomous robots is taking its first steps, and while right now they are still mostly found in factories and warehouses, they’ll soon be out in the wider world.

Autonomous robots are becoming more common

What’s certain is the number of robots around us continues to grow. According to the International Federation of Robots, we’re seeing record growth in the number of new robots, with over 550,000 new robots arriving in 2022, the most recent year for which it has data.

That means there are now roughly four million industrial robots in use around the world, with electronics, automotive, machinery, chemicals, and food – the industries most likely to use them. Around 290,000 of those new robots were installed in China, compared to 39,000 in the US.

And the growth is unlikely to stop: the industry body expects 700,000 new robots to arrive in 2026.

Sign up today and you will receive a free copy of our Future Focus 2025 report - the leading guidance on AI, cybersecurity and other IT challenges as per 700+ senior executives

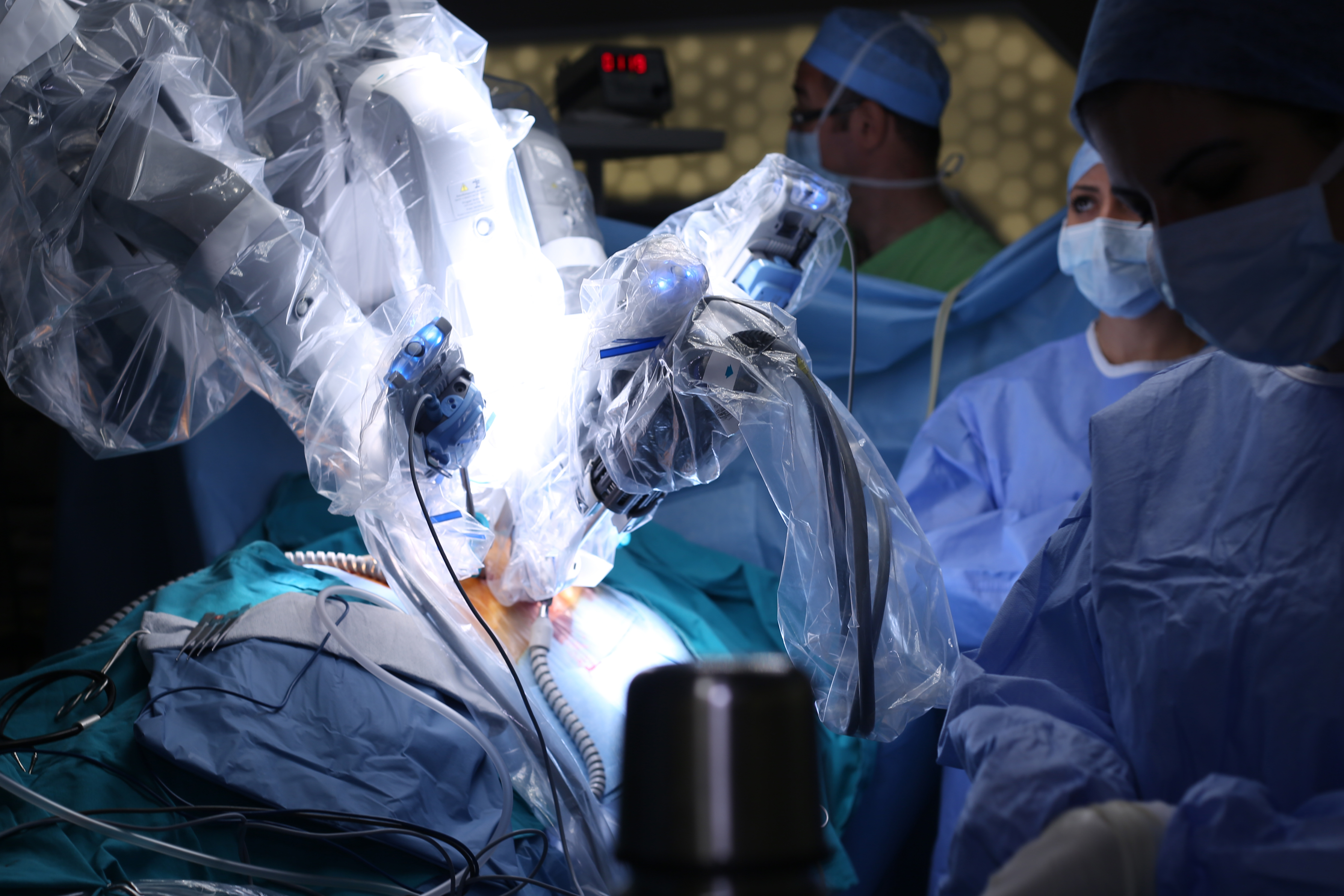

And then you have the 150,000 new service robots operating cleaning, hospitality, healthcare, and agriculture or delivering food. Consumer devices factor in here too, with around 40 million robot vacuum cleaners out there in the world, nimbly avoiding chair legs or giving lifts to cats right now. And of course, there are driverless cars, effectively autonomous robots on wheels, as well as drones which have applications for package delivery, fighting wildfires, and even helping deliver core healthcare services.

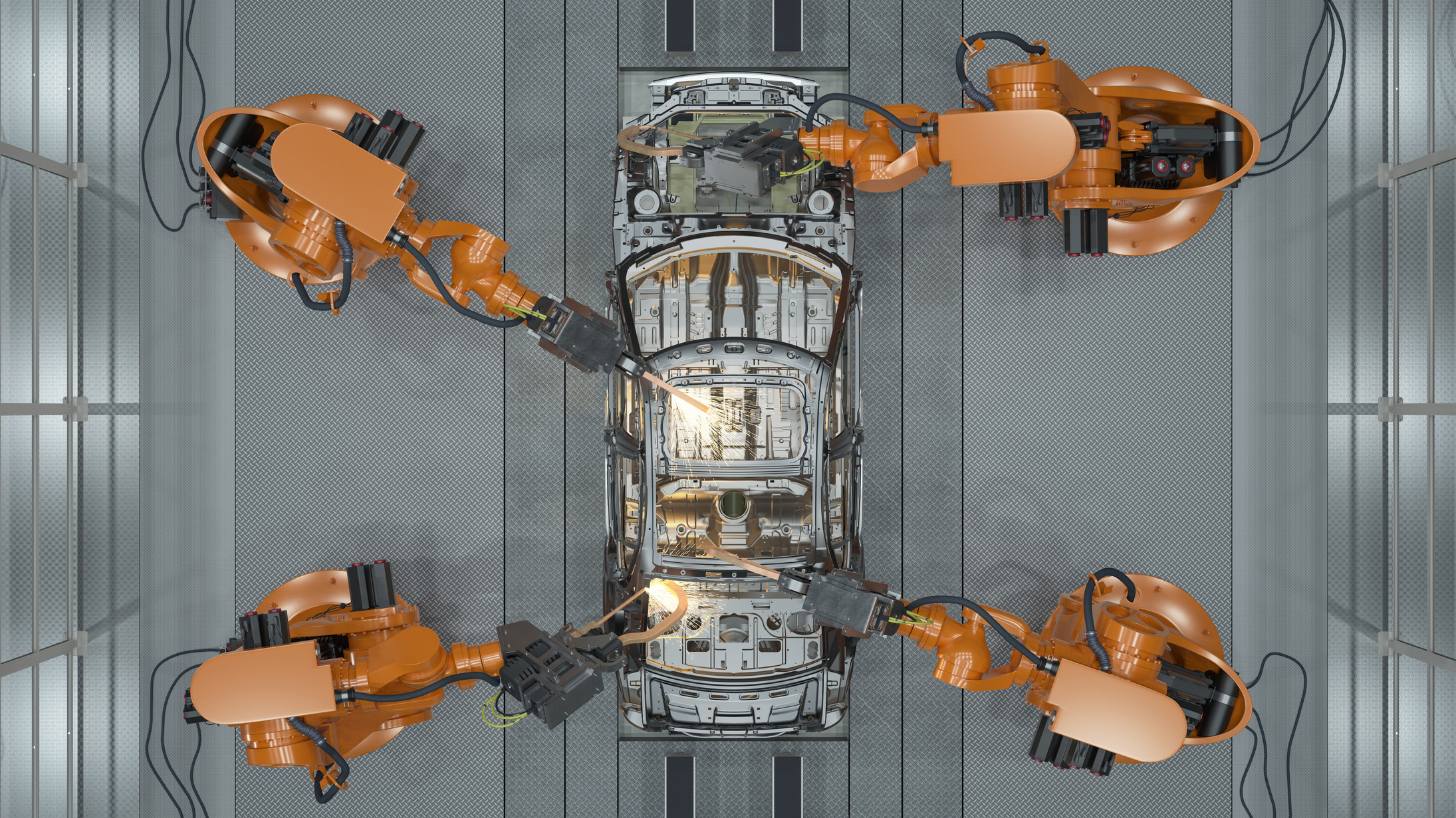

Autonomous robots in manufacturing

The first wave of robots in manufacturing didn’t have much in the way of intelligence or mobility. They were fixed in place and knew how to do one thing, like weld a part or paint a panel.

And they kept away well away from humans.

“Industrial robots work really well because there are no humans. You automate a factory: it’s full of robots, but there’s no randomness, no chaos,” says Watson. Over the last decade, companies have been experimenting with giving robots more autonomy, gifting them the ability to take on more complex jobs and even start to mix with humans.

There are a number of tech trends fuelling this growth in autonomous robots: cloud computing, edge computing, and 5G are making it easier to process data from robots and connect with them wherever they are. Machine learning (ML) and AI are also supporting developments in areas like computer vision, making it easier for robots to maneuver, sort and pick products, and engage with the world around them. But there is still plenty of work to do.

“The biggest challenge with autonomous robots at the moment, is that they don’t deal well with uncertainty, and humans are the most uncertain thing in the world. You try to put a robot into a human environment where people do random things, where you can’t predict what people are going to do, and there are big issues,” says Watson.

As a result, autonomous robots have so far sprung up largely in high-tech warehouses and factories which are effectively doubling as schools for the next generation of autonomous robots. These environments boast private 5G networks that allow robots to transmit and receive large amounts of data from external sensors in near real-time. The advent of 5G mmWave technology has improved this picture, as it allows for far higher throughput in areas of high congestion making it perfect for busy factory floors. 5G mmWave’s consistently low latency will also help autonomous robots react to their surroundings with little to no delay.

Compared to the street or a supermarket full of shoppers, a warehouse is a well-ordered space that isn’t going to change much. There isn’t too much to distract or confuse a robot as it works, perhaps moving pallets from one place to another or sorting and delivering items.

The real-world benefits of autonomous robots

Autonomous robots can be used to automate the most intense manual labor, such as moving heavy boxes around a storage environment or performing repetitive tasks such as placing products onto a conveyor belt.

Amazon is probably one of the best-known robot innovators. The tech giant has a range of fully autonomous warehouse robots comprising around a dozen different systems and about 750,000 robots in total doing a variety of jobs. This includes Cardinal, which is able to sort packages using AI and computer vision and Proteus, an autonomous robot that can lift carts filled with goods. Its Hercules robot can lift up to 1,250 pounds, uses a 3D camera to navigate around a warehouse – and can identify staff wearing Wi-Fi transmitters so it can plot a path around them.

Other roles we are likely to see autonomous robots taking first are the ones that are too challenging and hazardous for people, like inspections of wind farms or nuclear power plants.

However, as the costs of autonomous robots slowly come down, there will be more and more scenarios where deploying them starts to make sense. Gradually the lessons learned in warehouses and other controlled settings will be used to allow robots to roam further.

RELATED RESOURCE

Discover how you can create the ideal customer experience

DOWNLOAD NOW

The key thing will be finding productive uses where the cost of the robot is reasonable compared to the value of the work that the robot is going to do, says Dwight Klappich, research vice president at tech analyst Gartner. “Most organizations that we talk to it’s not ‘if’ they are going to do robots. its ‘where when and how many?’,” he says.

Labor costs are going up but the real driver for many companies is that they just can’t get enough people or hold on to them, he says. He says this is an issue even in lower-cost labor environments because bosses complain their workforce can be unreliable.

“They just don’t know who is going to show up for work in the morning,” he says.

One perhaps unexpected area of growth for autonomous robots already is in customer-facing roles in hospitality. Robots are capable of delivering food and cleaning surfaces, with price points that make sense in the long term and free up human workers to spend more time interacting directly with customers

Social care is another sector where robots could help, but this may take another decade or so to be widespread. That’s because there are still quite a few hurdles to the deployment of autonomous mobile robots into the world around us.

The hurdles autonomous robots face

It still takes a lot of expensive processing power for the real-time perception that these robots would need. As autonomous robots begin to employ ML, AI, or natural language processing (NLP) this processing burden will only increase and firms may be forced to equip robots with ‘local’ machine learning in a bid to cut costs.

More prosaically, battery life is one of the biggest limitations for mobile robots which can only operate for a few hours without needing to recharge. In many cases, autonomous robots can cost hundreds of thousands of dollars, which can be hard to justify except in cases where harm to workers is prevented or profits will be measurably improved through the introduction of autonomous robots. A firm grip on business intelligence (BI) and usage of big data analytics could help leaders assess the cost-benefit of autonomous robots in their workflow.

Will we ever see autonomous robots that look like us? This remains a point of contention. Humanoid robots might look cool (or terrifying depending on how many times you’ve seen The Terminator) but finding a use case for them is relatively tricky. But the biggest challenge for autonomous robots outside of controlled settings is that we haven’t really worked out all the rules for how they should behave and who gets the blame when things go wrong – and that human behavior is so hard to predict.

“Robots interacting with humans is a big challenge - and that’s why you don’t see many of them around,” says Watson.

Steve Ranger is an award-winning reporter and editor who writes about technology and business. Previously he was the editorial director at ZDNET and the editor of silicon.com.

-

I couldn’t escape the iPhone 17 Pro this year – and it’s about time we redefined business phones

I couldn’t escape the iPhone 17 Pro this year – and it’s about time we redefined business phonesOpinion ITPro is back on smartphone reviews, as they grow more and more intertwined with our work-life balance

-

The gig economy: Past, present, and future

The gig economy: Past, present, and futureFeature The rise of the gig economy represents a new era of flexible working despite being plagued with controversies

-

The Forrester Wave™: Robotic Process Automation Services

The Forrester Wave™: Robotic Process Automation ServicesWhitepaper The 15 providers that matter most and how they stack up

-

MOV.AI’s robotics engine platform aids AMR production

MOV.AI’s robotics engine platform aids AMR productionNews New platform automates autonomous mobile robot development with visual IDE, open API framework, 3D physics simulator, and more

-

ANYbotics taps Velodyne to enhance autonomous robots’ navigation

ANYbotics taps Velodyne to enhance autonomous robots’ navigationNews ANYbotics will incorporate Velodyne’s Puck Lidar sensors into its mobile robots

-

Infostretch and Automation Anywhere join forces to deliver hyperautomation

Infostretch and Automation Anywhere join forces to deliver hyperautomationNews New deal will help organizations establish RPA centers of excellence

-

Telepresence medical robot market set to reach $159.5 million by 2028

Telepresence medical robot market set to reach $159.5 million by 2028News Increasing adoption of robots in health care settings and product innovations are contributing to the market's growth

-

Boston Dynamics announces commercial sales of Spot Robot

Boston Dynamics announces commercial sales of Spot RobotNews Boston Dynamics launches its first online sales offering with Spot Robot

-

Changing the Games: Why Tokyo 2020 will be the most technologically advanced Olympics yet

Changing the Games: Why Tokyo 2020 will be the most technologically advanced Olympics yetIn-depth Japan is hoping to amaze athletes and fans alike at the upcoming Tokyo 2020 Olympics, with a host of cutting-edge innovations. Can it deliver on its promise?

-

Google sells robot arms to SoftBank

Google sells robot arms to SoftBankNews Boston Dynamics and SHAFT snapped up by Japanese firm