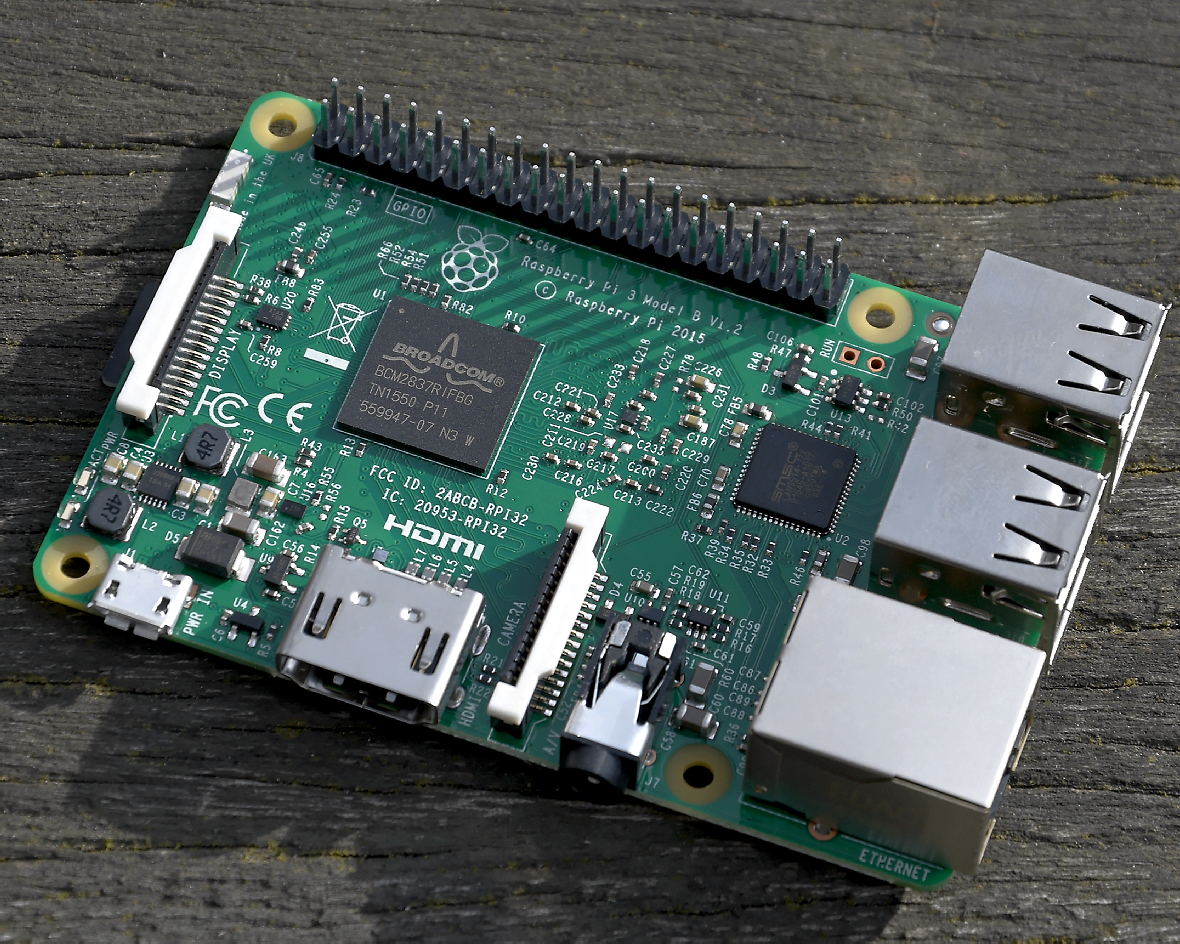

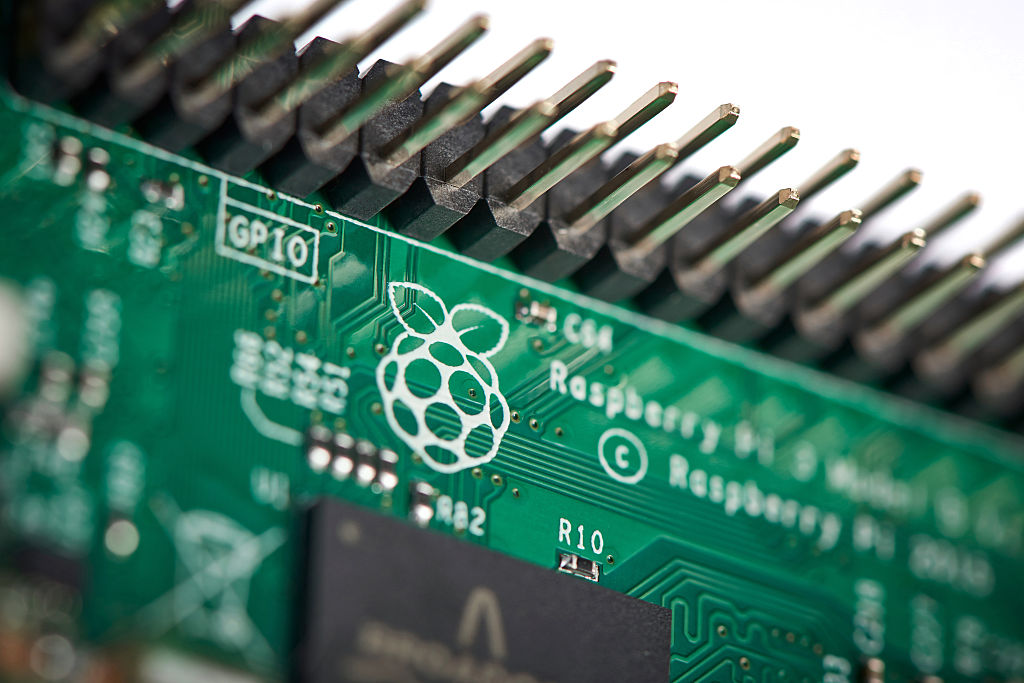

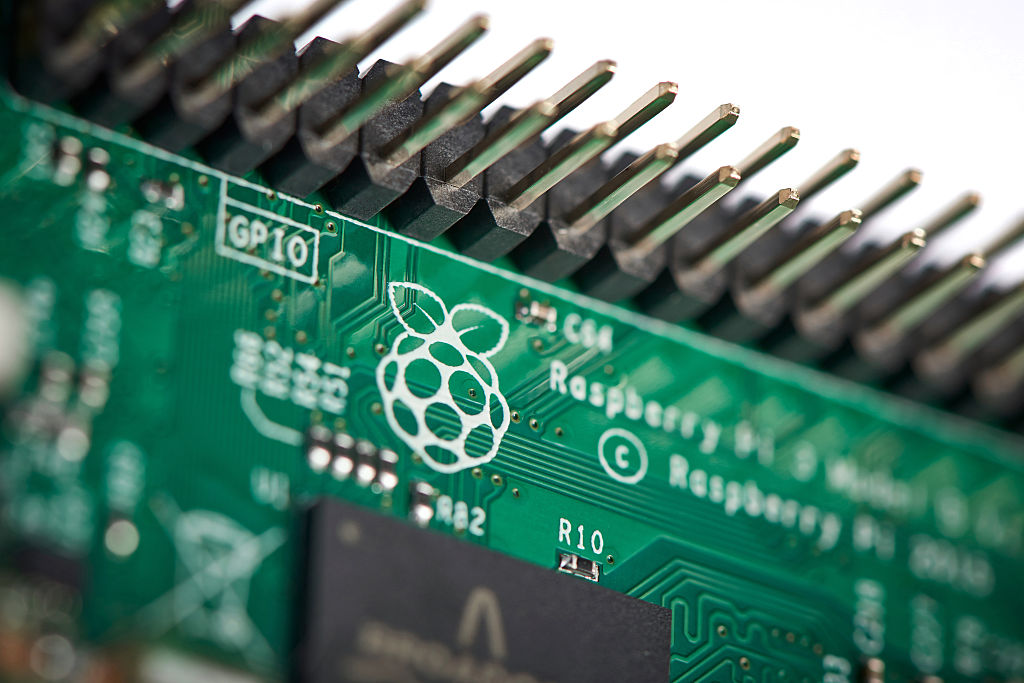

Sony celebrates building 10 million Raspberry Pi devices

The majority of the Japanese manufacturer's microcomputers have been produced in Wales

Sony has revealed it's manufactured 10 million of the 14 million Raspberry Pi devices it's shipped so far in Wales, putting the tiny country on the map as a major tech producer.

In fact, the Japanese manufacturer has committed so much to producing the microcomputers in Wales, it's had to more than double its staff in the region to ensure it can keep up with supply demands.

"The last five years has seen unprecedented growth across our Pencoed facility, something we are understandably incredibly proud of," Sony's UK TEC managing director Steve Dalton said.

"Our growth has been intrinsically linked to the success of the Raspberry Pi and we are delighted to reach the 10m manufacturing milestone. This is a significant achievement for everyone involved in its production, especially our devoted Sony Team, the Raspberry Pi Foundation, and distributors Premier Farnell."

He went on to say that it's has a huge impact on helping Wales grow its presence in the tech sector, manufacturing a low-cost electronics device at such a high volume.

Raspberry Pi's creator Eben Upton also praised the workforce and the efforts of Sony and its partners, saying it has contributed a lot to the microcomputer's success.

"The last five years has been extremely exciting for us as we watched the Raspberry Pi become Britain's best-selling computer of all time," he said. "We are particularly delighted that the Pi has set the benchmark for utilising innovative and progressive manufacturing right here in the UK, as it was always our wish to make the computers in this country."

Get the ITPro daily newsletter

Sign up today and you will receive a free copy of our Future Focus 2025 report - the leading guidance on AI, cybersecurity and other IT challenges as per 700+ senior executives

Despite the successes to date, Upton thinks it's still going to take time before Raspberry Pi 4 is ready for release, saying technical developments are holding the foundation back from being able to develop the next iteration of the device.

"We're kind of at the end of the road for 40 nanometer," he said. "There's not much more you can do in that process, because ultimately you're limited by thermals. In the end, you can add as much silicon area as you want, because if you can't afford to toggle the transistors in the silicon because the thing will cook, then you can't get any faster."

Clare is the founder of Blue Cactus Digital, a digital marketing company that helps ethical and sustainability-focused businesses grow their customer base.

Prior to becoming a marketer, Clare was a journalist, working at a range of mobile device-focused outlets including Know Your Mobile before moving into freelance life.

As a freelance writer, she drew on her expertise in mobility to write features and guides for ITPro, as well as regularly writing news stories on a wide range of topics.

-

Third time lucky? Microsoft finally begins roll-out of controversial Recall feature

Third time lucky? Microsoft finally begins roll-out of controversial Recall featureNews The Windows Recall feature has been plagued by setbacks and backlash from security professionals

By Emma Woollacott Published

-

The UK government wants quantum technology out of the lab and in the hands of enterprises

The UK government wants quantum technology out of the lab and in the hands of enterprisesNews The UK government has unveiled plans to invest £121 million in quantum computing projects in an effort to drive real-world applications and adoption rates.

By Emma Woollacott Published

-

Arm acquires stake in Raspberry Pi in bid to drive IoT development

Arm acquires stake in Raspberry Pi in bid to drive IoT developmentNews The deal confirms a long-standing Raspberry Pi commitment to Arm chips

By Emma Woollacott Published

-

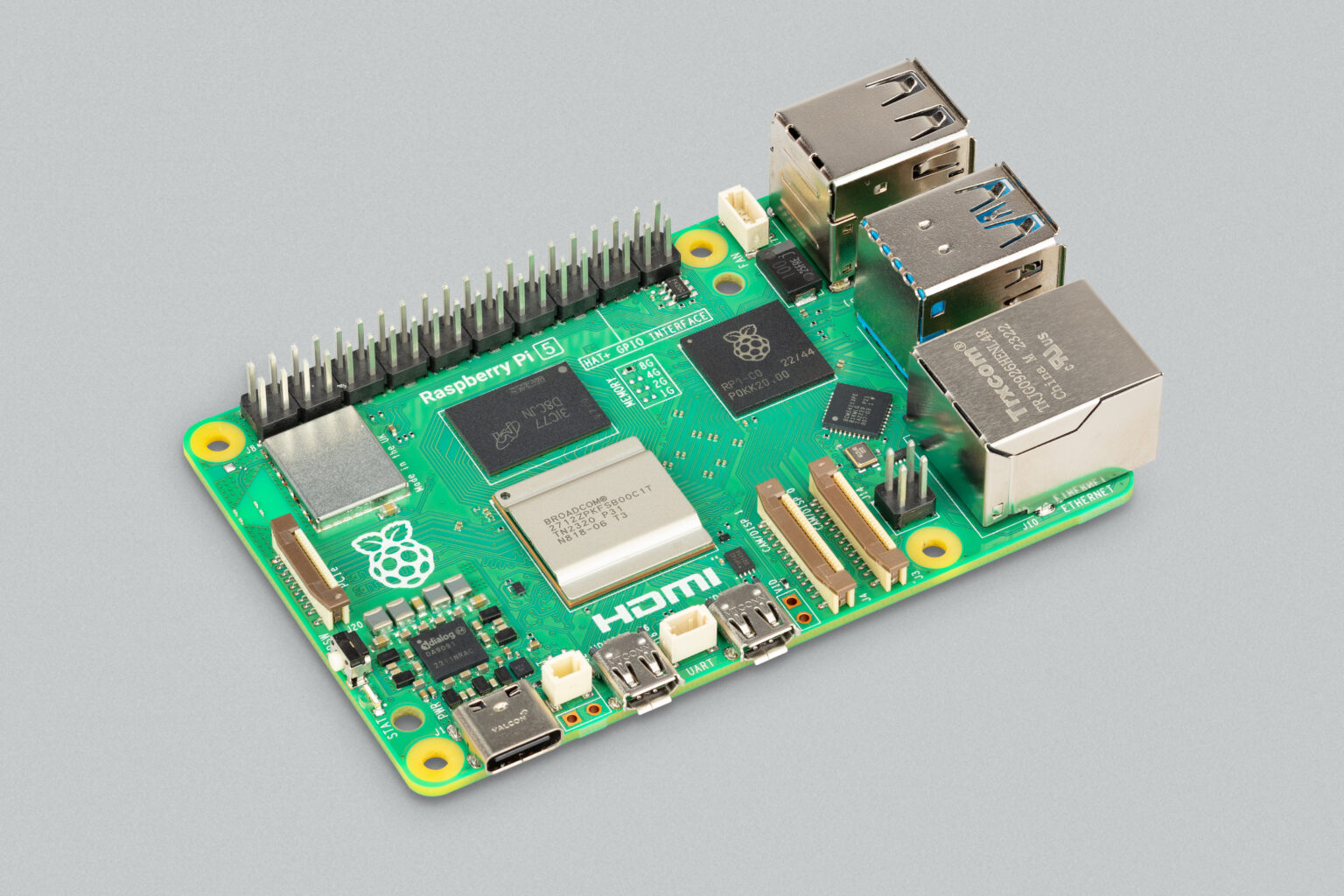

Raspberry Pi 5: New model is “2-3 times more powerful” than previous generation

Raspberry Pi 5: New model is “2-3 times more powerful” than previous generationNews The new Raspberry Pi 5 will provide a “no-compromise user experience”, the firm said

By Ross Kelly Published

-

Sony invests in Raspberry Pi to strengthen edge AI offering

Sony invests in Raspberry Pi to strengthen edge AI offeringNews The move follows longstanding ties between the two firms

By Ross Kelly Published

-

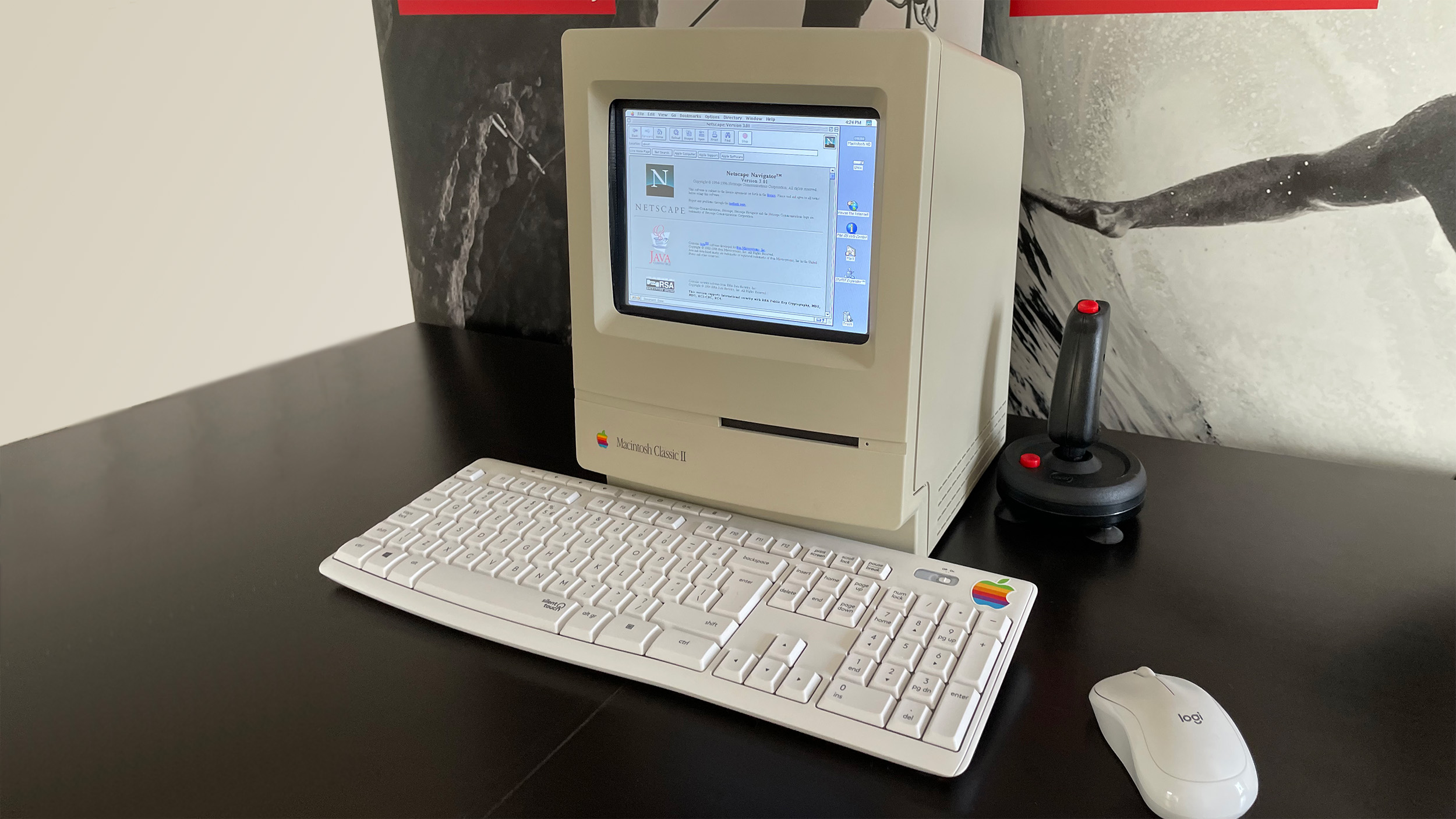

Return of the Mac

Return of the MacIn-depth Developer Jarosław Mazurkiewicz explains the creative process behind MacintoshPi and why he wanted to bring a classic Mac back to life

By David Crookes Published

-

Raspberry Pi ten years on: Breathing new life into retro machines

Raspberry Pi ten years on: Breathing new life into retro machinesIn-depth A full decade after the Raspberry Pi first hit shelves, the microcomputer is reviving older PCs and games consoles

By David Crookes Published

-

The IT Pro Podcast: Turning developers into craftspeople

The IT Pro Podcast: Turning developers into craftspeopleIT Pro Podcast Making software is about much more than pushing code, explains Raspberry Pi founder Eben Upton

By IT Pro Published

-

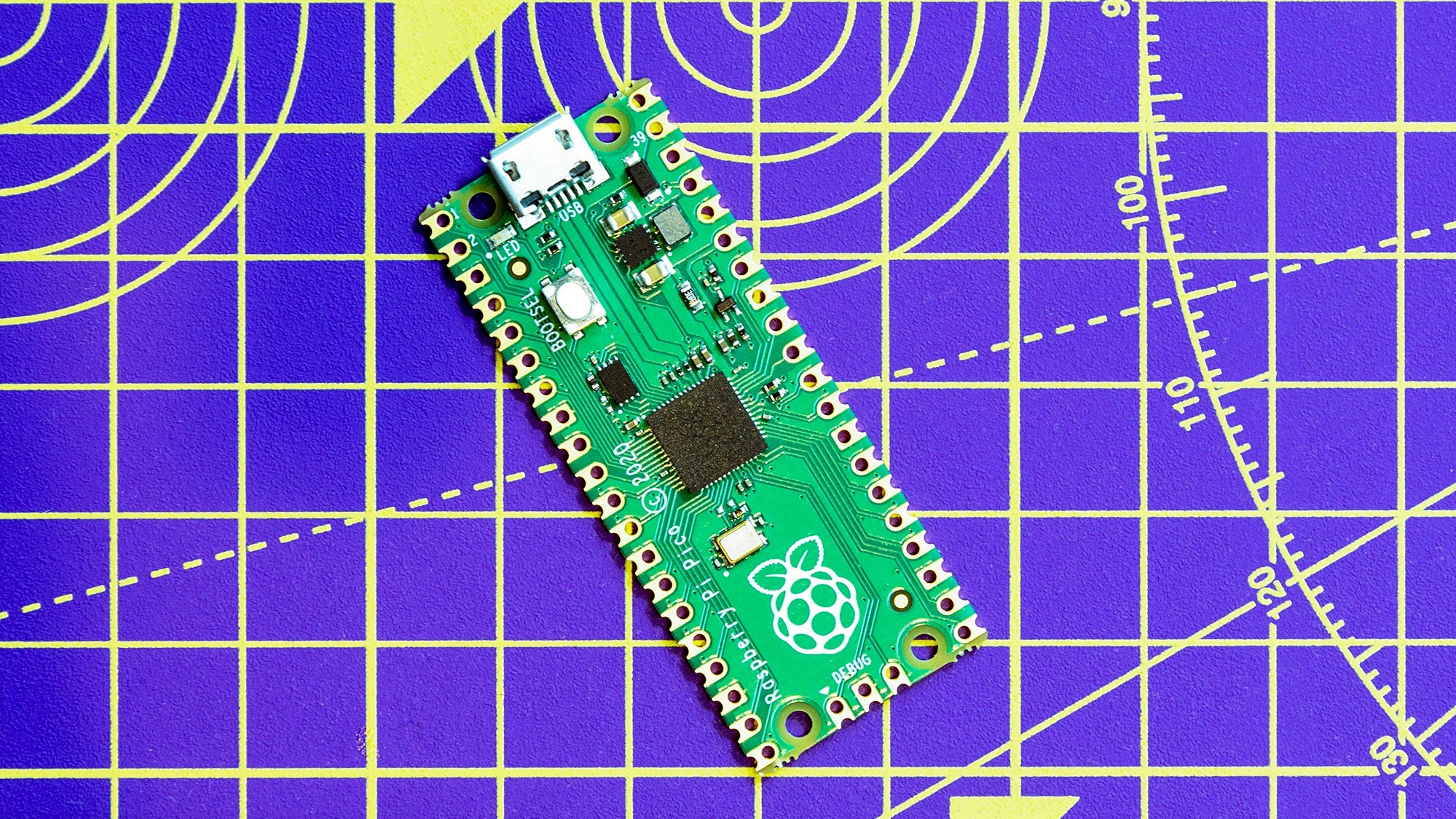

What is the Raspberry Pi Pico?

What is the Raspberry Pi Pico?In-depth Introducing the latest $4 member of the family of single-board microcomputers

By Keumars Afifi-Sabet Published

-

Raspberry Pi 4 gets an official case fan

Raspberry Pi 4 gets an official case fanNews The £4.50 fan will prevent the board's ARM Cortex-A72 processor from overheating

By Rene Millman Published