3D printed drone success hailed by Sheffield university

Engineers claim trial success could pave the way for disposable drones.

University of Sheffield engineers claim to have successfully created a 1.5 metre-wide unmanned aerial vehicle (UAV), or drone, using 3D printing techniques.

The engineering team are part of the university's Advanced Manufacturing Research Centre, and used the fused deposition modelling (FDM) 3D printing technique to create the aircraft.

This method requires material to be laid down in layers in order to create the finish product.

Previous attempts at creating similar devices, without using 3D printing, were marred by lengthy build times and high production costs, the University claims.

The aircraft reportedly consists of nine parts that can be snapped together, and weighs just under 2kg.

The group hope the low costs involved with creating the drone will pave the way for the building of disposable unmanned aircraft that can be sent on one-way flights for reconnaissance and search purposes.

The device has already completed a test flight as a glider, and the engineering team are now in the throes of developing an electric ducted fan propulsion system for flying purposes.

Get the ITPro daily newsletter

Sign up today and you will receive a free copy of our Future Focus 2025 report - the leading guidance on AI, cybersecurity and other IT challenges as per 700+ senior executives

The team also hopes the craft will eventually be guided on its flights by GPS or camera technology, which will be controlled by an operator wearing first person-view goggles.

Dr Garth Nicholson, the project's leader, said the team are also working on a number of other features to enhance the aircraft's capabilities.

These include the use of nylon as a printing material, because it would make the device 60 per cent stronger without affecting its overall weight.

"We are also investigating full on-board data logging of flight parameters, autonomous operation by GPS, and control by surface morphing technology. Concepts for novel ducted fan designs are also being investigated," Nicholson revealed.

The past year has seen a raft of research projects and real-world deployments of 3D printing techniques come to light, with the medical field fast emerging as a keen adopter of the technology.

As reported by IT Pro yesterday, the technique has been used to create a new skull for a lady suffering with a debilitating illness.

Furthermore, several high street retailers have recently started stocking consumer-focused 3D printers, although analysts have said the price of these will need to drop significantly if the technology is to catch on in the home.

-

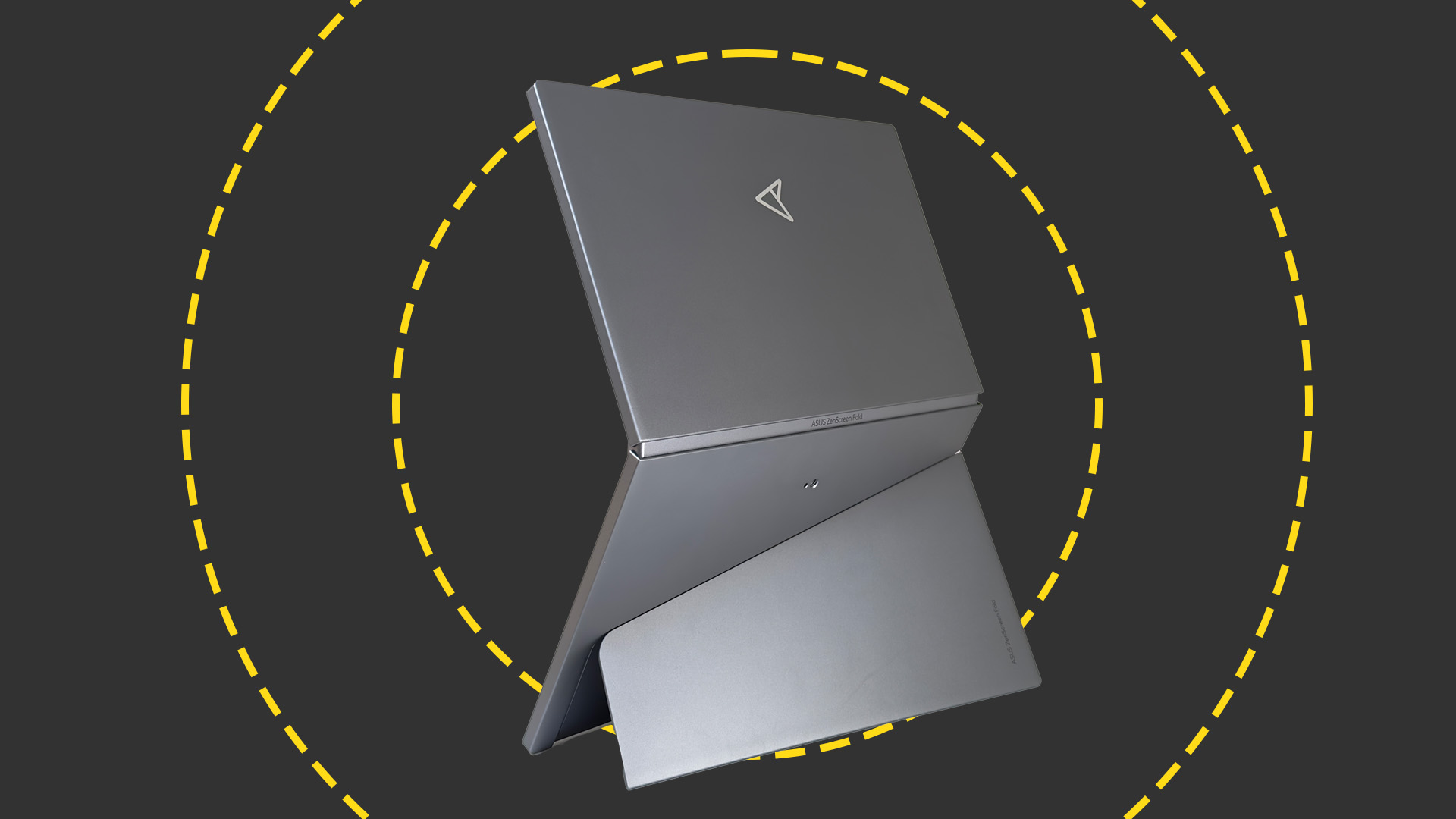

Asus ZenScreen Fold OLED MQ17QH review

Asus ZenScreen Fold OLED MQ17QH reviewReviews A stunning foldable 17.3in OLED display – but it's too expensive to be anything more than a thrilling tech demo

By Sasha Muller

-

How the UK MoJ achieved secure networks for prisons and offices with Palo Alto Networks

How the UK MoJ achieved secure networks for prisons and offices with Palo Alto NetworksCase study Adopting zero trust is a necessity when your own users are trying to launch cyber attacks

By Rory Bathgate